Hyundai Tucson: Engine Control System / Injector

| Item | Specification |

| Coil Resistance (Ω) | 11.4 - 12.6 |

| Item | Specification |

| Coil Resistance (Ω) | 1.43 - 1.58 |

1.In the engine control system, failure can be quickly diagnosed by using the diagnosis tool.

(1)Self diagnosis : Checking failure and code number (DTC).

(2)Current data : Checking the system input/output data state.

(3)Actuation test : Checking the system operation condition.

(4)Additional function : Controlling other features including system option setting and zero point adjustment.

1.Turn the ignition switch OFF.

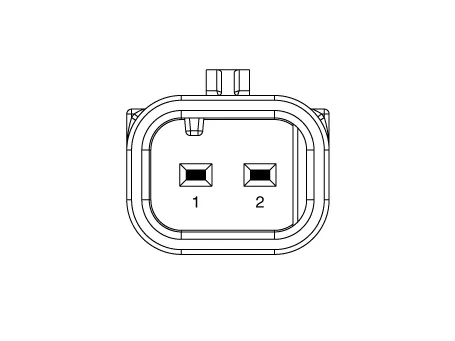

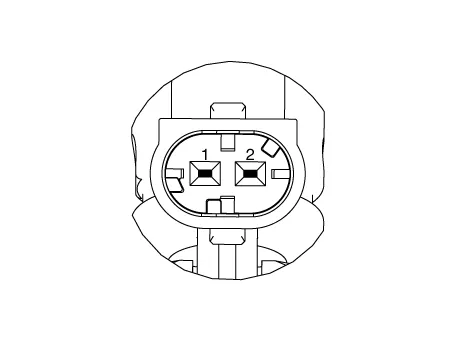

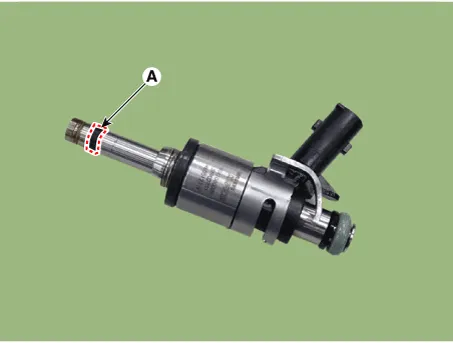

2.Disconnect the injector connector.

3.Check that the resistance is within the specification.

Specification : Refer to "Specification"

1.Release the residual pressure in fuel line.(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line")

2.Turn the ignition switch OFF and disconnect the battery negative (-) cable.

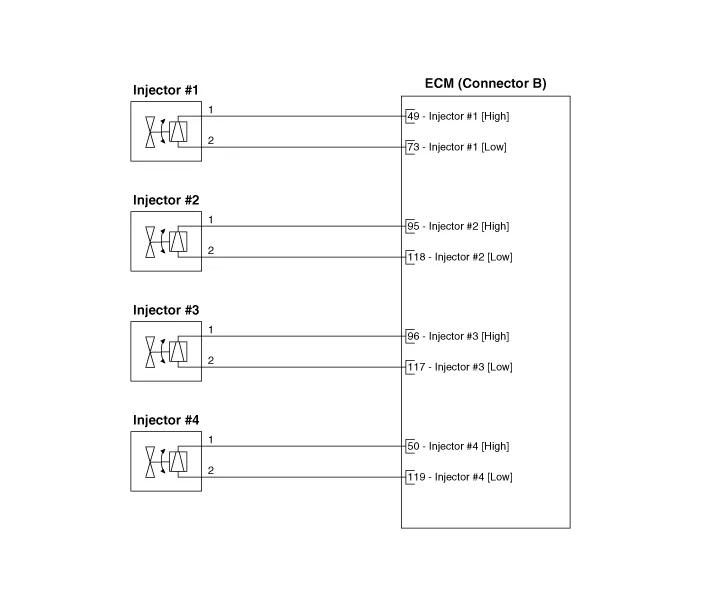

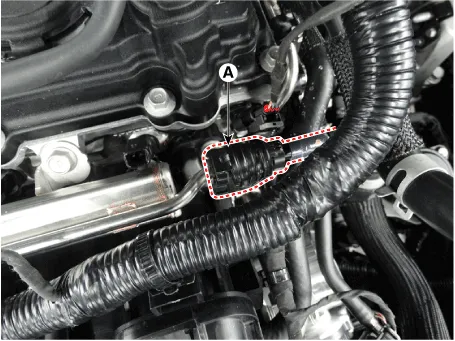

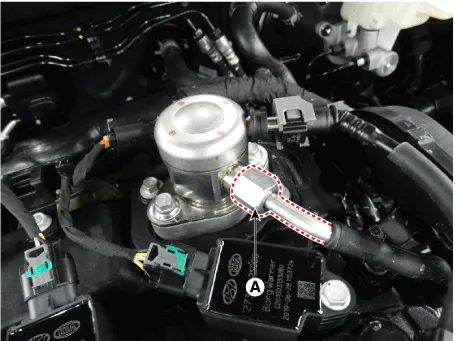

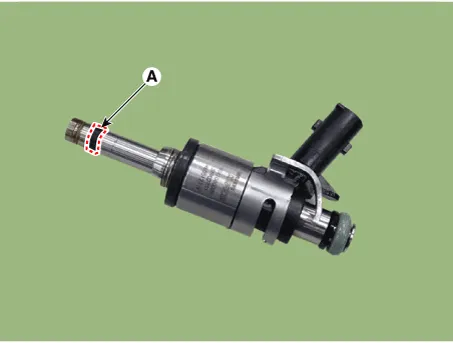

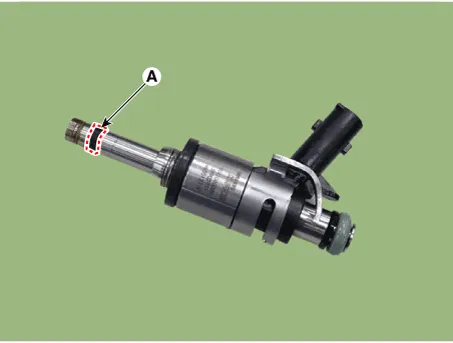

3.Disconnect the injector connector (A).

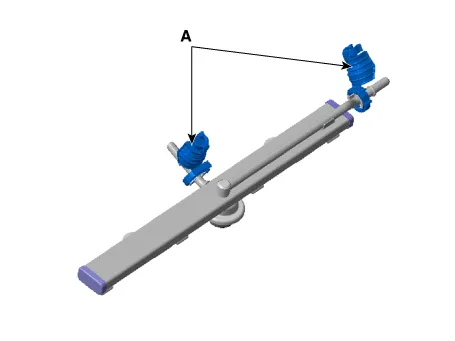

4.Disconnect the fuel feed quick-connector (A).

• Open the clamp cover (A) before disconnecting the quick-connector. (If the clip is applied)

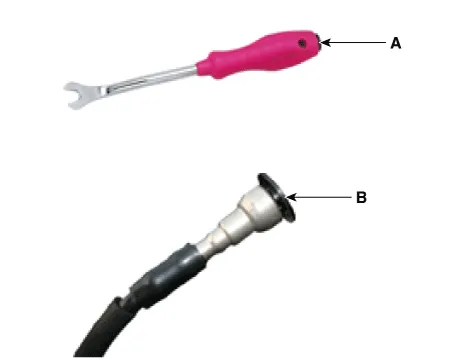

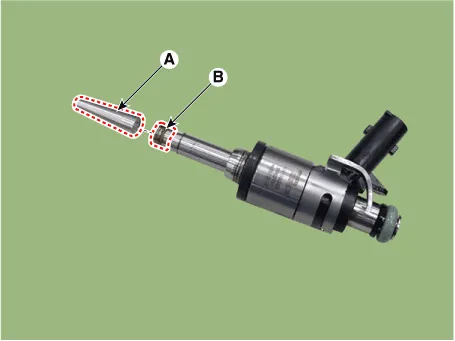

• When removing the quick-connnector with the clip removing tool (A), be careful not to damage the plastic clip (B).

• If the clip is damaged, it can cause a fuel leak due to bad connection and could result in a fire.

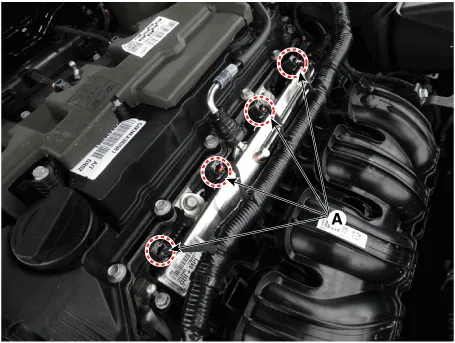

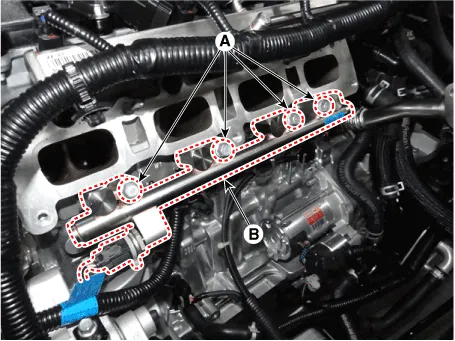

5.Remove the delivery pipe after loosening the mounting bolt (A).

Tightening Torque :18.6 - 23.5 N.m (1.9 - 2.4 kgf.m, 13.7 - 17.3 lb-ft)

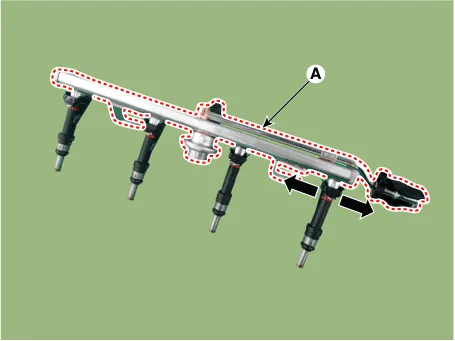

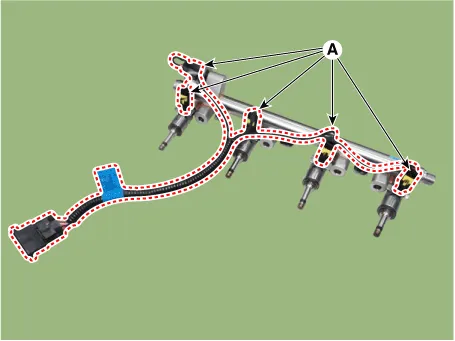

6.Remove the injector from the delivery pipe (A) after releasing the fixing clip both side as shown below.

1.Release the residual pressure in fuel line.(Refer to Fuel Delivery System - "Release Residual Pressure in Fuel Line")

2.Turn the ignition switch OFF and disconnect the battery negative (-) cable.

3.Remove the air cleaner assembly.(Refer to Engine Mechanical System - "Air Cleaner")

4.Remove the intake manifold.(Refer to Engnie Mechanical System - "Intake Manifold")

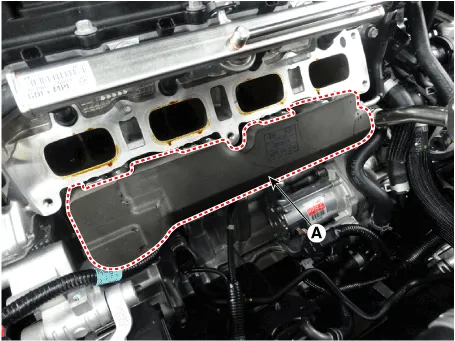

5.Remove the injector foam (A).

6.Loosen the high pressure fuel pipe bracket mounting bolt (A) and then loosen the flange nut (B,C).

Tightening Torque A : 9.8 - 11.8 N.m (1.0 - 1.2 kgf.m, 7.2 - 8.7 lb-ft)B, C : 26.5 - 32.4 N.m (2.7 - 3.3 kgf.m, 19.5 - 23.9 lb-ft)

7.Loosen the mountin bolt (A) and then remove the delivery pipe & injector assembly (B).

Tightening Torque :18.6 - 23.5 N.m (1.9 - 2.4 kgf.m, 13.7 - 17.3 lb-ft)

8.Disconnect the injector & rail pressure sensor connector (A).

9.Remove the injector from the delivery pipe (A) after releasing the fixing clip both side as shown below.

1.Install in the reverse order of removal.

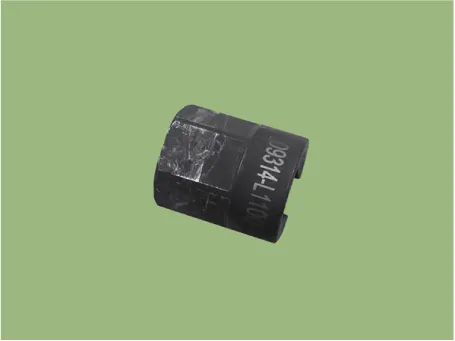

• When tightening the high pressure fuel pipe flenge nut (A), using a SST (SST No. : 09314-L1100).

• Using a spanner torque wrench (27mm).

• Do not reuse the high pressure fuel pipe.

• Note that do not deforming the high pressure fuel pipe.

• Install the component with the specified torques.

• Install the high pressure fuel pipe and then check the oil leakage.

• When Installing the high pressure fuel pipe, using a SST (SST No. : 09314-L1100).

(1)When reusing the injector refer to below.

• When removing/reinstalling the injector, clean the cylinder head hole and the appearance.(Removal of carbon deposits and foreign substances using a brush)

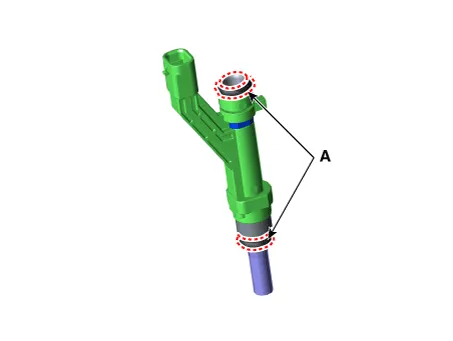

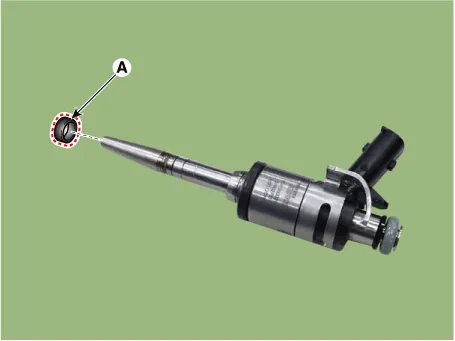

• Be careful not to apply oil/grease/lubricant to the combustion seal (A).

• Do not use the dropped part.

• When inserting the injector, be careful not to damage the injector tip.

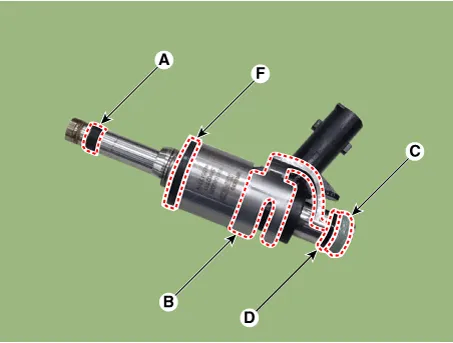

• Do not reuse the combustion seal (A), injector clip (B), O-ring (C), support disk (D), rubber washer (F).

• Be careful not to apply oil to combustion seal.

• Do not reuse the O-ring (A).

• Apply the engine oil to the injector O-ring.

• When inserting the injector, be careful not to damage the injector tip.

• In order to prevent from oil leak, replacement of combustion seal should follow the below procedure.

1.Remove the combustion seal (A).

• Be careful not to damage the injector while remove the combustion seal.

• Remove the combustion seal using a nipper.

2.Before the assembly of the sealing ring the groove must be cleaned using a clean cloth.

3.Install the combustion seal using a special service tool (SST No. :09353-L1100).

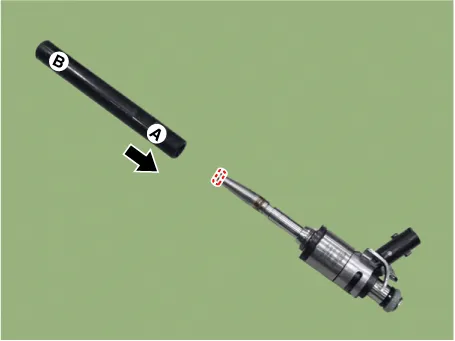

(1)Place the seal installing guide (A) (SST No.: 09353-2B000) on the tip of the injector not to damage the injector tip (B).

(2)Install the combustion seal (A) to the seal installing guide.

(3)Input the seal to A direction of the installer, and push it to B direction until it reaches the combustion seal installation area.

• The complete assembly must not take longer than 2 to 3 seconds.

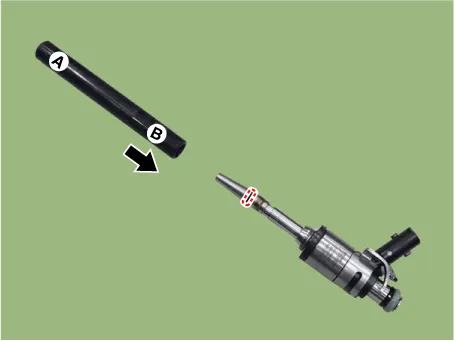

(4)Install the compressor (A) and disconnect it after rotating 3-4 times to left and right direction.

(5)Check the combustion seal (A) installation.

Fuel Tank Pressure Sensor (FTPS)

Fuel Tank Pressure Sensor (FTPS)

- Description

Fuel Tank Pressure Sensor (FTPS) is a component of the evaporative

emission control system and is installed on the fuel tank, the fuel

pump, or the canister. It checks the purge c ...

Purge Control Solenoid Valve (PCSV)

Purge Control Solenoid Valve (PCSV)

- Description

Purge Control Solenoid Valve (PCSV) is a solenoid valve and is

installed on the surge tank and controls the passage between the

canister and the intake manifold.The evaporative ga ...

Other information:

Hyundai Tucson (NX4) 2022-2025 Service Manual: Torque Converter Clutch Control Solenoid Valve (T/CON_VFS)

- Description

• Torque converter control solenoid valve (T/CON_VFS) is attached to the valve body.

• This variable force solenoid valve indirectly controls the hydraulic pressure inside the torque converter.

- Components Location

1. 28 Brake control solenoid valve (28/B_VFS)2. 4 ...

Hyundai Tucson (NX4) 2022-2025 Owner's Manual: Vehicle Auto-Shut Off

If your vehicle is parked and the engine

is left on for a long period of time, the

engine turns off automatically to help

reduce fuel consumption and prevent

carbon dioxide poisoning.

Operating Conditions

Vehicle Auto-Shut Off timer operates

when all the following conditions are

satisf ...