Hyundai Tucson: General Service Information / General Information

• The support rod must be inserted into the hole near the edge of the hood whenever you inspect the engine compartment to prevent the hood from falling and causing possible injury.

• Make sure that the support rod has been released prior to closing the hood. Always make sure the hood is firmly latched before driving the vehicle.

1)Inspection of partsEach part, when removed, should be carefully inspected for malfunction, deformation, damage, and other problems.

2)Arrangement of partsAll disassembled parts should be carefully arranged for effective reassembly.Be sure to separate and distinguish the parts to be replaced from those that will be used again.

3)Cleaning parts for reuseAll parts to be used again should be carefully and thoroughly cleaned in an appropriate method.

1)Oil seals

2)Gaskets

3)O-rings

4)Lock washers

5)Cotter pins (split pins)

6)Plastic nuts

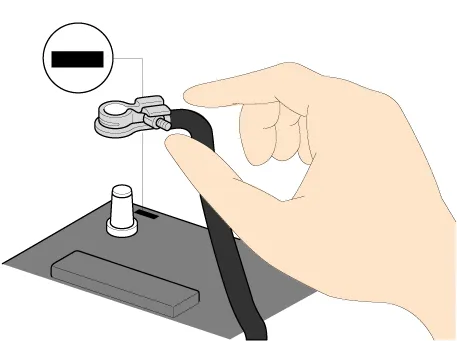

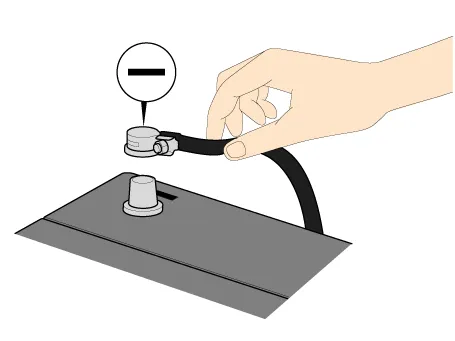

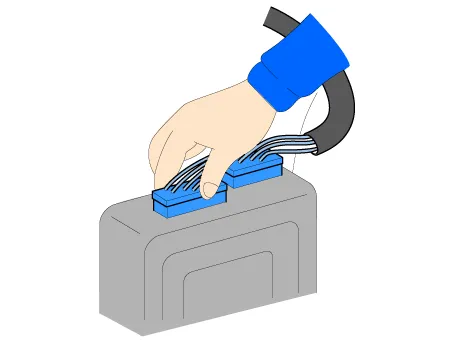

1.Be sure to disconnect the battery cable from the negative (-) terminal of the battery.

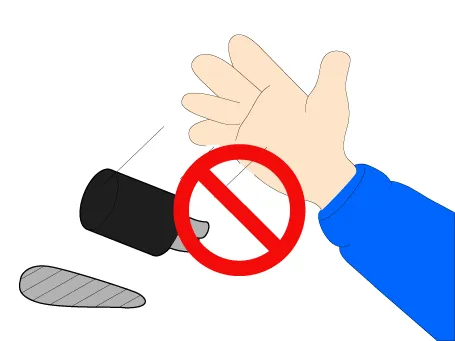

2.Never pull on the wires when disconnecting connectors.

3.Locking connectors will click when the connector is secure.

4.Handle sensors and relays carefully. Be careful not to drop them against other parts.

1.Check the terminal for tightness.

2.Check terminals and wires for corrosion from battery electrolyte, etc.

3.Check terminals and wires for open circuits.

4.Check wire insulation and coating for damage, cracks and degrading.

5.Check whether the conductive parts of terminals contact other metallic parts (vehicle body and other parts).

6.Check whether there is complete continuity between the attaching bolt(s) of the grounded parts and the vehicle’s body.

7.Check for incorrect wiring.

8.Check the wiring is clamped to prevent contact with sharp corners of the vehicle body, or hot parts (exhaust manifold, pipe, etc.)

9.Check that the wiring is clamped firmly to provide enough clearance from the fan pulley, fan belt and other rotating or moving parts.

10.Check that the wiring has a little space so that it can vibrate between the fixed (the vehicle body) and moving parts (wirings, engine, etc.)

1.Prior to servicing the electrical system, make sure to turn off the ignition switch and disconnect the battery ground cable.

• In the course of MFI or ELC system diagnosis, when the battery cable is removed, any diagnostic trouble code retained by the computer will be cleared. There fore, if necessary, record the diagnostic data before removing the battery cable.

2.Fix the wiring harnesses with clamps so that there is no slack wiring. However, for any harness which passes the engine or other vibrating parts of the vehicle, allow some slack within a range that does not allow the engine vibrations to cause the harness to come into contact with any of the surrounding parts and then secure the harness by using a clamp.

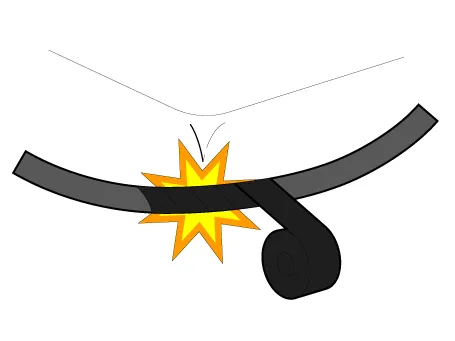

3.If any section of a wiring harness interferes with the edge of a part, or a corner, wrap the section of the harness with tape or something similar in order to protect it from damage.

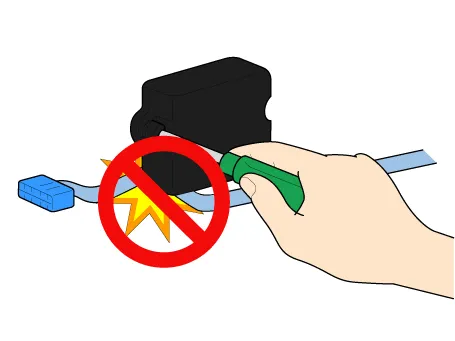

4.When installing any parts, be careful not to pinch or damage any of the wiring harness.

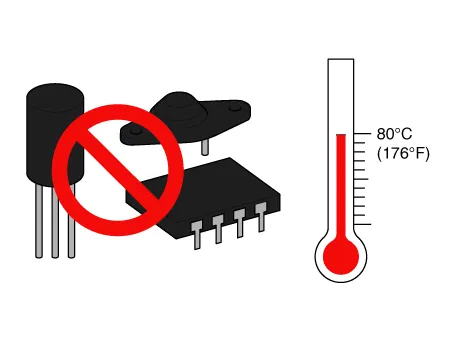

5.Never throw relays, sensors or electrical parts, or expose them to strong shock.

6.The electronic parts used in the computer, relays, etc. are easily damaged by heat. If there is a need for service operations that may cause the temperature to exceed 80°C (176°F), remove the electronic parts beforehand.

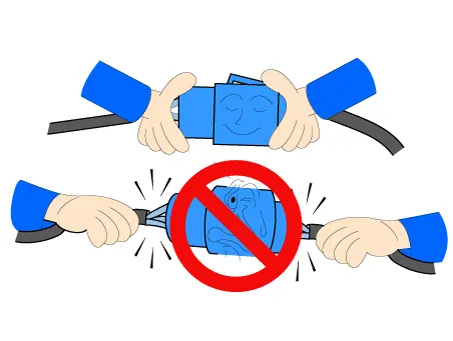

7.Loose connectors may cause malfunction. Make sure that the connectors are always securely fastened.

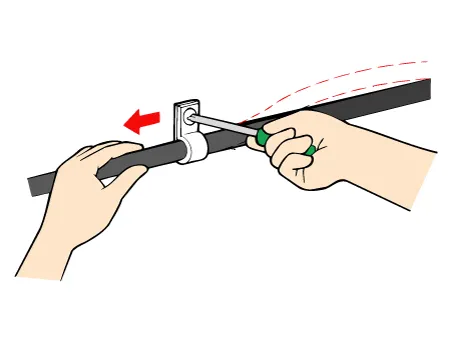

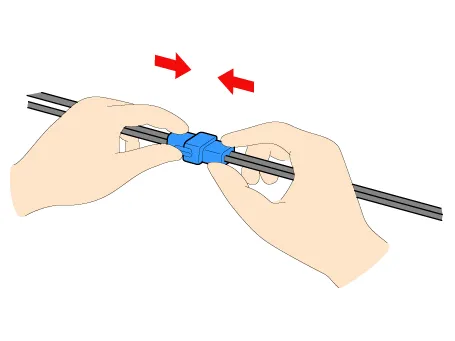

8.When disconnecting a connector, be sure to grip only the connector, not the wires.

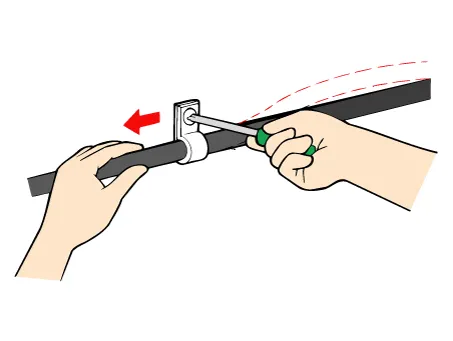

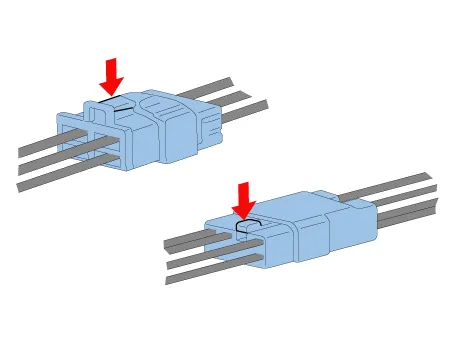

9.Disconnect connectors which have catches by pressing in the direction of the arrows shown in the illustration.

10.Connect connectors which have catches by inserting the connectors until they make a clicking sound.

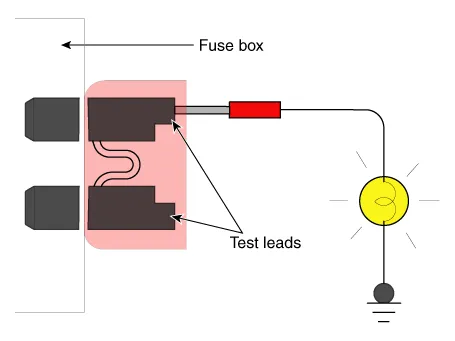

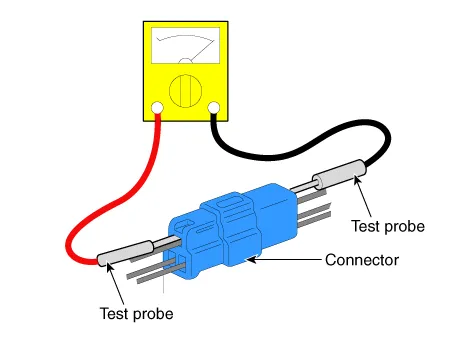

11.When using a circuit tester to check continuity or voltage on connector terminals, insert the test probe into the harness side. If the connector is a sealed connector, insert the test probe through the hole in the rubber cap until the probe contacts the terminal, being careful not to damage the insulation of the wires.

12.To avoid overloading the wiring, take into consideration the electrical current load of the optional equipment when determining the appropriate wire size.

| Recommended size | SAE gauge No | Permissible current | |

| In engine compartment | Other areas | ||

| 0.3mm² | AWG 22 | - | 5A |

| 0.5mm² | AWG 20 | 7A | 13A |

| 0.85mm² | AWG 18 | 9A | 17A |

| 1.25mm² | AWG 16 | 12A | 22A |

| 2.0mm² | AWG 14 | 16A | 30A |

| 3.0mm² | AWG 12 | 21A | 40A |

| 5.0mm² | AWG 10 | 31A | 54A |

• If a large amount of unburned gasoline flows into the converter, it may overheat and create a fire hazard. To prevent this, observe the following precautions and explain them to customers.

1.Use only unleaded gasoline.

2.Do not run the engine while the car is at rest for a long time. Avoid running the engine at fast idle for more than 10minutes and at idle speed for more than 20 minutes.

3.Do not measure engine compression for an extended time. Engine compression tests must be made as rapidly as possible. Remove the fuel pump relay before performing a compression test.

4.Do not dispose of used catalytic converter together with parts contaminated with gasoline or oil.

Other information:

Hyundai Tucson (NX4) 2022-2025 Owner's Manual: Auto Hold

Auto Hold maintains the vehicle in a

standstill even though the brake pedal is

not depressed after the driver brings the

vehicle to a complete stop by depressing

the brake pedal.

Information

When the vehicle is restarted, the last

setting for Auto Hold is applied.

To apply:

Type A

...

Hyundai Tucson (NX4) 2022-2025 Service Manual: Repair procedures

- Removal

1.Disconnect the negative (-) battery terminal.

2.Remove the heater control unit.(Refer to Heating, Ventilation And Air Conditioning - "Heater Control Unit")

3.Remove the IBU (A) after loosening mounting bolt, nut and screw.

4.Disconnect IBU connectors and then remove the IBU (A) ...