Hyundai Tucson: Driveshaft Assembly / Joint Assembly (Transaxle side)

• Drive shaft joints require special grease, so do not add any other type of grease.

• When replacing the boot band, it must be a new one.

1.Remove the front drive shaft.(Refer to Driveshaft Assembly - "Front Driveshaft")

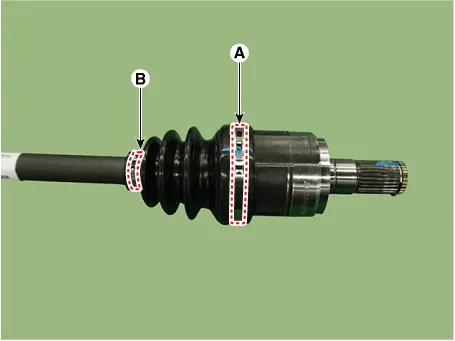

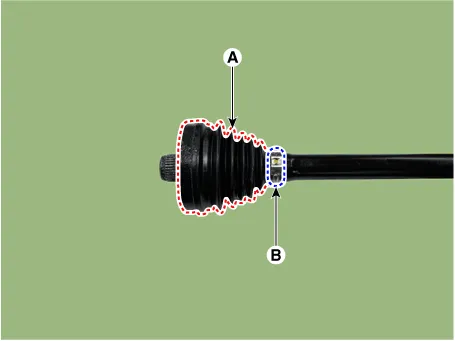

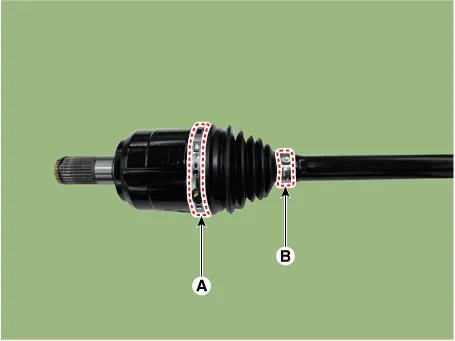

2.Remove the transaxle side large diameter (A) and small diameter (B) boot bands.

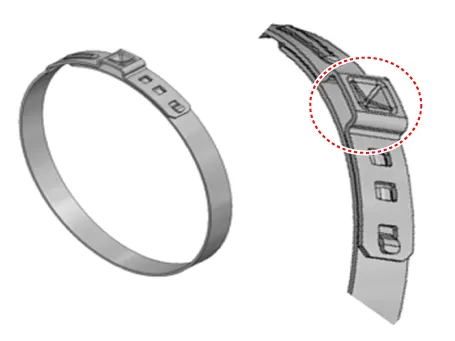

• Use the right tool for each type of boot band as shown in the table below.

| Ear type | Hook type | Hook type [Low profile] |

| Driver (-) | Driver (-) | SST (0K495-2W000) |

|

|

|

|

|

|

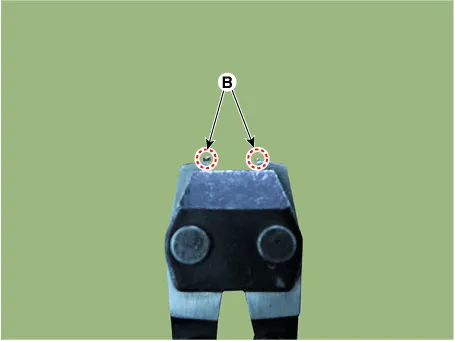

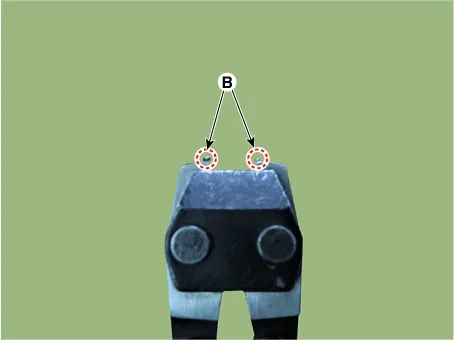

• When using the low profile hook type boot band, fit the SST tip (B) into the boot band hole (A) as shown below.

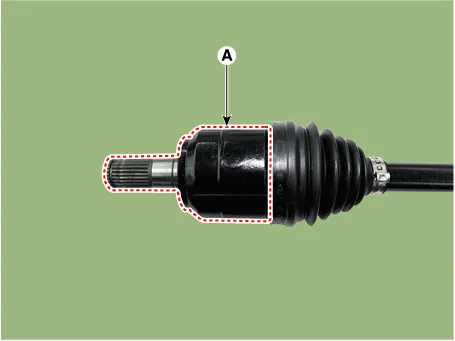

3.Remove the trans axle joint housing (A).

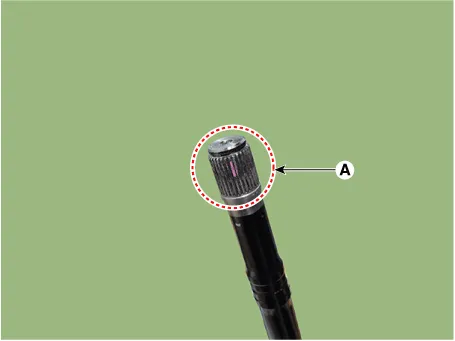

4.Remove the snap ring (A) using a snap ring pliers.

5.Remove the spider assembly (A) from the drive shaft using a puller.

6.Remove trans axle side boot (A).

7.Clean the inside of the spider assembly and joint housing.

• Remove grease inside the housing as much as possible.

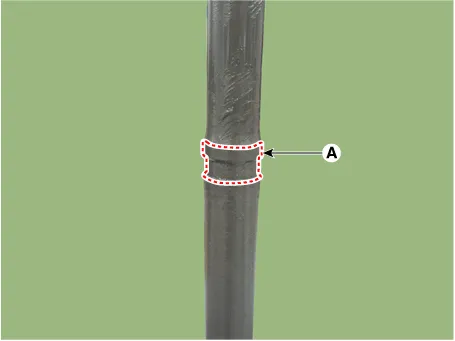

1.Check spline (A) for damage / wear / crack.

2.Check the boot for water or foreign objects.

3.Check joint assembly for damage / wear / crack and rust.

4.Replace any defective parts.

• When assembling, be careful not to let dust and foreign substances enter.

• Driveshaft joints require special grease, so do not add any other type of grease.

• Boot bands must use the new one.

1.Install the transaxle side boot (A) and boot band (B) on the driveshaft.

• Put the boot band (B) first on the drive shaft before installing the boot (A).

• When installing the boot, seats in the mounting part (A).

2.Install the spider assembly (A) on the shaft (B), then press it using a mallet.

• When installing the spider assembly (A), install it in the correct direction.

• Installing in the wrong direction can cause secondary quality problems.

• When installing the spider assembly, install it according to the boot shape.

3.Install the snap ring (A) using the snap ring pliers.

• When replacing the joint assembly, use the new one provided in the joint kit.

• The snap ring must be new.

• After installing the snap ring, make sure that there are only 2 - 3 splines in position (A).

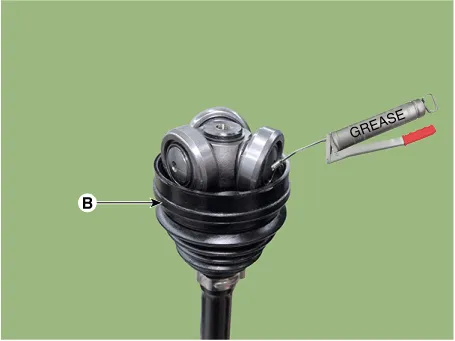

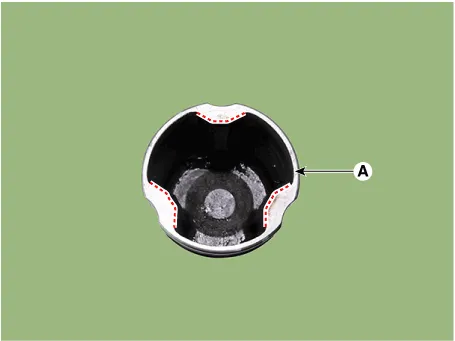

4.Apply specified grease inside the joint housing (A) and boot (B).

• Use the grease provided with the joint/boot kit.

• Apply about 70% grease to the housing (A) and about 30% grease to the boot (B).

• Driveshaft joints require special grease, so do not add any other type of grease.

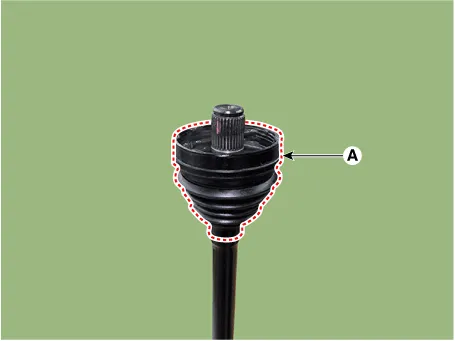

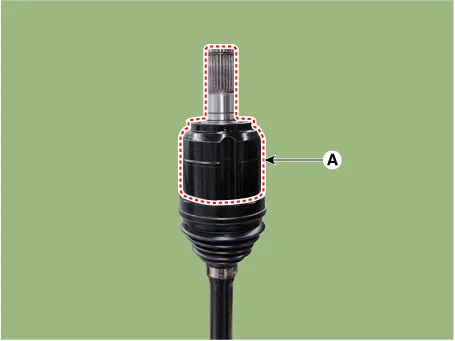

5.Install the trans axle side joint housing (A).

• When installing the housing, turn the boot to fit each other.

• If the shape of housing and boot does not fit, there is a possibility of leakage due to the gap. Be very careful.

6.Adjust the air inside the boot to normal as shown below.

| Normal | Lack of air | Too much air |

|

|

|

• After installing the joint housing, perform air bleeding by pressing it several times until no air is heard.

7.Install the transaxle side joint large diameter (A) and small diameter (B) boot band.

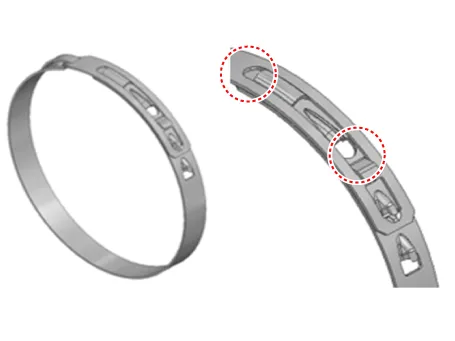

| Ear type | Hook type | Hook type [Low profile] |

| SST (0K495-C5000) | SST (09495-39100) | SST (0K495-2W000) |

|

|

|

|

|

|

• Install in the following order: large diameter boot band → small diameter boot band.

• Installing in the wrong order can cause leaks.

• When installing the ear type boot band, check the clearance (A) as shown below.

Clearance (A) : 2.0 mm or less.

• When using the low profile hook type boot band, fit the SST tip (B) into the boot band hole (A) as shown below.

8.Install the front driveshaft.(Refer to Driveshaft Assembly - "Front Driveshaft")

Dynamic Damper

Dynamic Damper

- Removal

1.Remove the front drive shaft.(Refer to Driveshaft Assembly - "Front Driveshaft")

2.Remove the trans axle side joint.(Refer to Driveshaft Assembly - "Transaxle Joint")

3.Remove the d ...

Joint Assembly (Wheel side)

Joint Assembly (Wheel side)

- Removal

The type can replace the wheel side joint boot

1.Remove the front drive shaft.(Refer to Driveshaft Assembly - "Front Driveshaft")

2.Remove the trans axle side joint.(Refer to Driveshaf ...

Other information:

Hyundai Tucson (NX4) 2022-2026 Owner's Manual: Cluster Display Message

(Button type)

Information

The actual message may differ from

the following cluster display message.

The following messages may differ

depending on the vehicle model.

Shifting conditions not met. Reduce

speed, then shift

This message appears when the engine

RPM is too high or when driving too f ...

Hyundai Tucson (NX4) 2022-2026 Service Manual: Rear Door Belt Outside Weatherstrip

- Replacement

1.Pull down the rear door window glass to the lowest level by pressing the power window glass switch.

2.Remove the rear door belt outside weatherstrip (A).

3.To install, reverse removal procedure.

• Replace any damaged clips (or pin-type retainers).

...