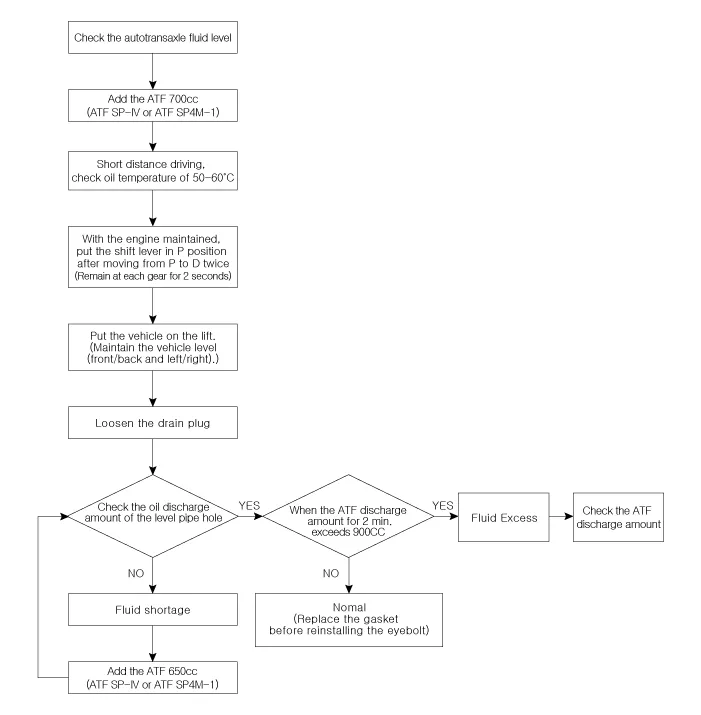

Hyundai Tucson: Automatic Transaxle System / Automatic Transaxle Fluid (ATF)

1. ATF Injection plug (Eyebolt)

2. ATF injection plug gasket

3. ATF level check plug

4. ATF level check plug gasket

5. Drain plug gasket

6. Drain plug

• When checking the oil level, be careful not to enter dust, foreign matters, etc. from fill hole.

• Be careful not to damage the parts located under the vehicle (floor under cover, fuel filter, fuel tank and canister) when raising the vehicle using the lift.(Refer to General Information - "Lift and Support Points")

1.Remove the air cleaner assembly.(Refer to Engine Mechanical System - "Air cleaner")

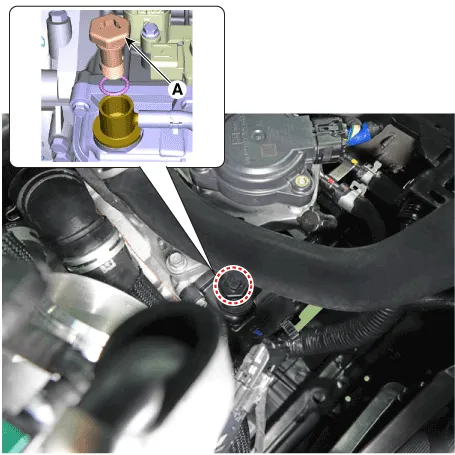

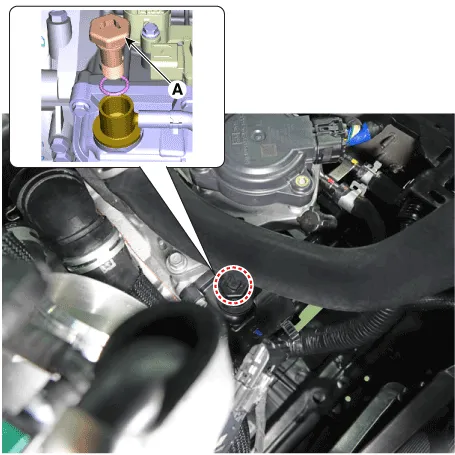

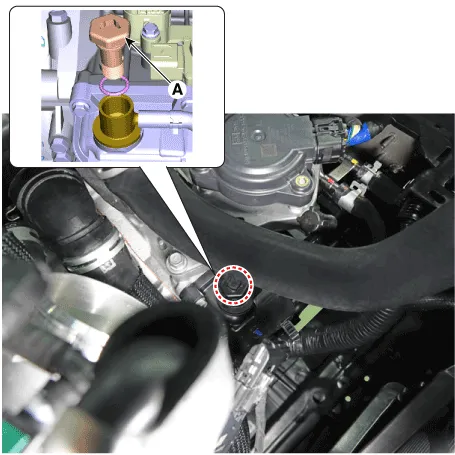

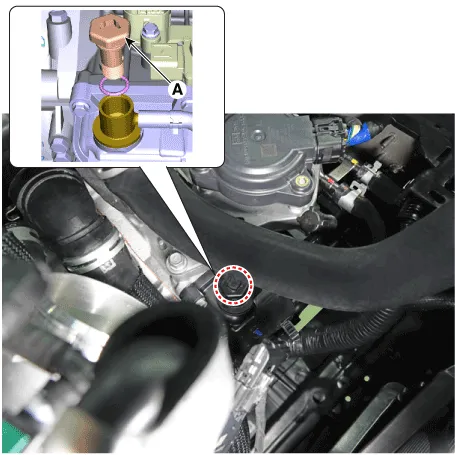

2. Remove the eyebolt (A).

3.Add ATF SP-IV or SP4M-1 700cc to the ATF injection hole (A).

4.Start the engine.(Don’t step on brake and accelerator simultaneously.)

5.Confirm that the temperature of the automatic transaxle oil temperature sensor is 50 - 60°C (122 - 140°F) with the diagnostic tool.

6.Shift the select lever slowly from “P” to “D”, then “D” to “P” and repeat one more at idle.

• Pause at each gear position more than 2 seconds.

7.Raise the vehicle, and make sure it is securely supported.

8.Remove the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")

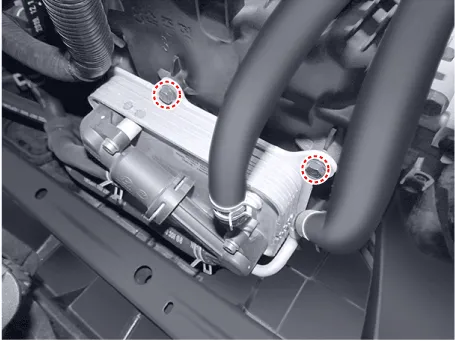

9.In case by ATF warmer, loosening the mounting bolts and then separate the ATF warmer (A).

Tightening torque :9.8 - 11.7 N·m (1.0 - 1.2 kgf·m, 7.2 - 8.6 lb-ft)

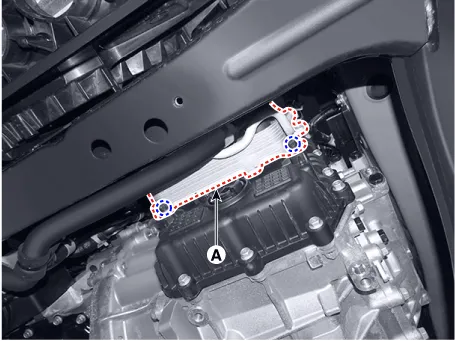

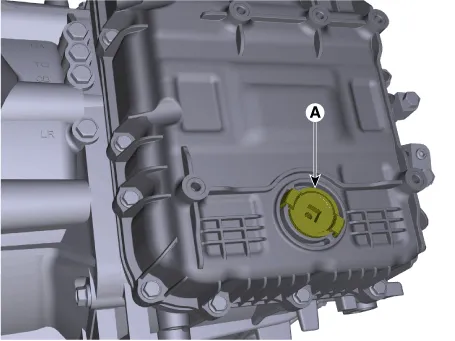

10. Remove the ATF level check plug (A) from the valve body cover.

• At this time, the vehicle must be at a level state.

11.If the ATF flows out of the overflow plug in thin steady stream, the ATF level is correct.Then finish the procedure and tighten the ATF level check plug.

• Excess : Drain quantity exceed 900cc for tow minutes. {50 - 60°C (122 - 140°F)}

• Shortage : No ATF flows out of the overflow plug.

• Replace the gasket before reinstalling the ATF level check plug.

• Turn the oil level check plug clockwise until it is set.

• If there is no damage at the automatic transaxle and the ATF cooler, the ATF cooler hose, transaxle case, valve body tightening state are normal, ATF must drip out after performing above 1 to 7 procedures. After performing above 1 to 7 procedures, if the oil doesn’t drip out, inspect the automatic transaxle assembly.

12. Install the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")

13.Put down the vehicle with the lift and then tighten the eyebolt (A).

Eyebolt tightening torque :4.9 - 5.9 N.m (0.5 - 0.6 kgf.m, 3.6 - 4.3 lb.ft)

• Replace the gasket (A) before reinstalling the eyebolt.

• Driving in rough road (Bumpy, Gravel, Snowy, Unpaved road, etc).

• Driving in mountain road, ascent / descent.

• Repetition of short distance driving.

• More than 50% operation in heavy city traffic during hot weather above 30°C (86°F) .

• Police, Taxi, Commercial type operation or trailer towing, etc.

• Be careful not to damage the parts located under the vehicle (floor under cover, fuel filter, fuel tank and canister) when raising the vehicle using the lift.(Refer to General Information - "Lift and Support Points")

1.Remove the air cleaner assembly.(Refer to Engine Mechanical System - "Air cleaner")

2.Remove the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")

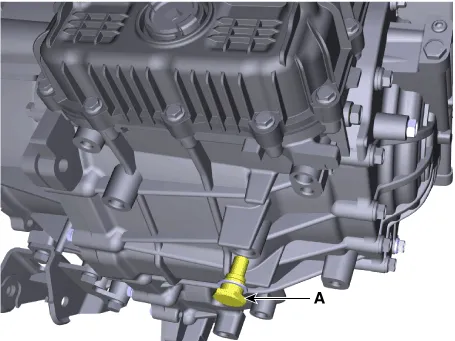

3. Remove the drain plug (A) and reinstall the drain plug after draining ATF totally.

• Replace the gasket before reinstalling the drain plug.

Drain plug tightening torque :33.3 - 43.1 N.m (3.4 - 4.4 kgf.m, 24.6 - 31.8 lb-ft)

4.Put down the vehicle with the lift and then remove the eyebolt (A).

5.Add ATF SP4M-1 about 5.0L to the ATF injection hole (A).

6.Check the ATF level.(Refer to Automatic Transaxle System - "Automatic Transaxle Fluid")

7.Then finish check the ATF level procedure and install the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")

8.Put down the vehicle with the lift and then tighten the eyebolt (A).

Eyebolt tightening torque :4.9 - 5.9 N.m (0.5 - 0.6 kgf.m, 3.6 - 4.3 lb.ft)

• Replace the gasket (A) before reinstalling the eyebolt.

9.Install the air cleaner assembly.(Refer to Engine Mechanical System - "Air cleaner")

Automatic Transaxle

Automatic Transaxle

- Removal

• Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and canister) when raising

the vehicle using the lift.( ...

Other information:

Hyundai Tucson (NX4) 2022-2025 Service Manual: Front Brake Caliper

- Components

1. Caliper body2. Caliper carrier3. Pad inner shim4. Pad retainer5. Brake pad

- Removal

• Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and canister) when raising

the vehicle using the lift. ...

Hyundai Tucson (NX4) 2022-2025 Owner's Manual: Drive Mode Integrated Control System

Type A

Type B

The drive mode can be selected

according to the driver’s preference or

road condition.

The system resets to NORMAL mode,

when the engine is restarted.

Information

If there is a problem with the instrument

cluster, the drive mode is in NORMAL

mode and may not change ...